Product description

pvc pipe making machine consists of conical twin-screw extruder, vacuum forming equipment, Haul-off machine, cutting machine, stacker and other components, with good stability, and produced high, easy to operate, reliable. The production line can produce water supply and drainage pipe, the material is U-PVC, C-PVC, large diameter PVC. Configure the secondary shunt mold, with a low temperature. Extrusion in low pressure; water membrane sizing, to ensure high-speed pipe production

Production flow

Raw material+agency----------mixing---loader-----force feeding-------extrusion------------extrusion mould-vacuum forming tank---spray cooling tank-oil printer---haul-off---cutter----stacker

Each part machinery's function introduction

(1),raw material mixing: is PVC stabilizers, plasticizers, antioxidants and other accessories, scale, technology has added into a high-speed mixer, the material and mechanical friction material from temperature to set the process temperature, and then the cold mixing machine material to 40-50 degrees; this can be added to the extruder hopper.

(2),The extruder portion: the machine equipped with a quantitative feeding device, so that the extrusion amount and feeding amount can be matched, to ensure that the products stable extrusion. Due to the characteristics of conical screw, a feeding section having a larger diameter, the material heat transfer area and the shear velocity is relatively large, is conducive to the plastics materials in metering section of screw, small diameter, reducing the heat transfer area and on the shear rate of melt, the melt at lower temperatures and extrusion. Screw in the barrel rotates, the PVC mixture plasticizing to head, thereby achieving compaction, melting, mixing and homogenizing; exhaust gas, dehydration of. The feeding device and a screw drive device with variable frequency speed control, can realize the synchronous speed control.

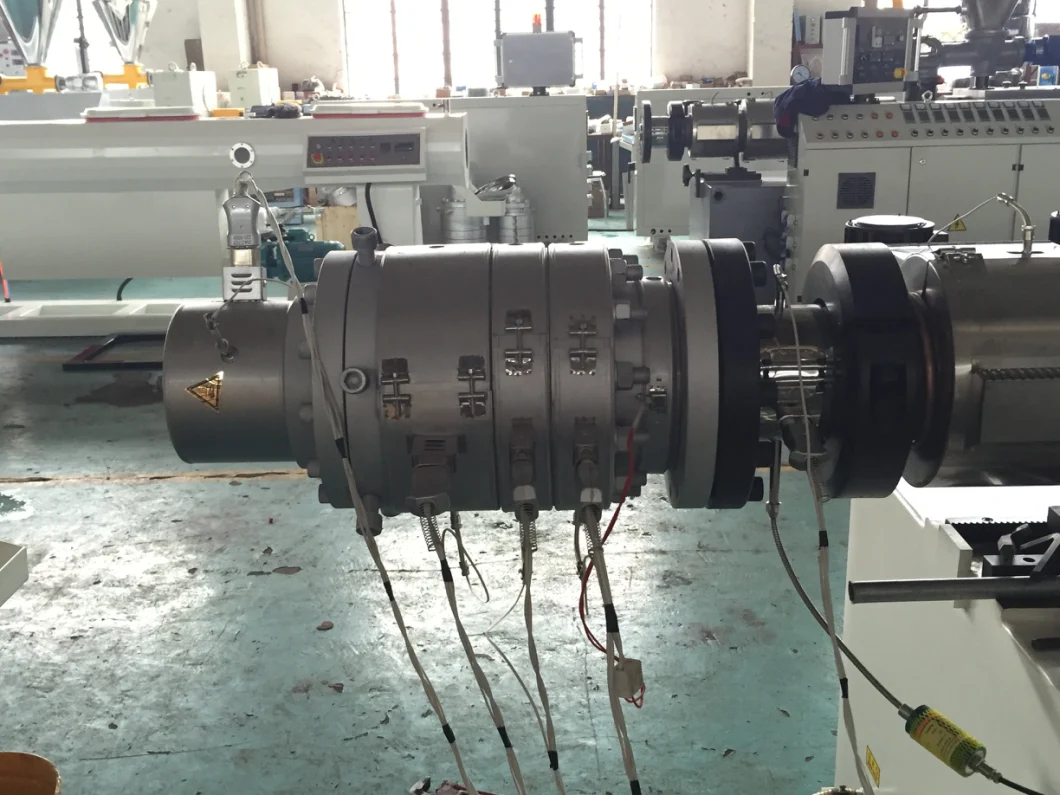

(3),Extrusion die head part : by compaction, melting, mixing of PVC, with follow-up materials by the screw to die, extrusion die head is the key part of the pipe forming

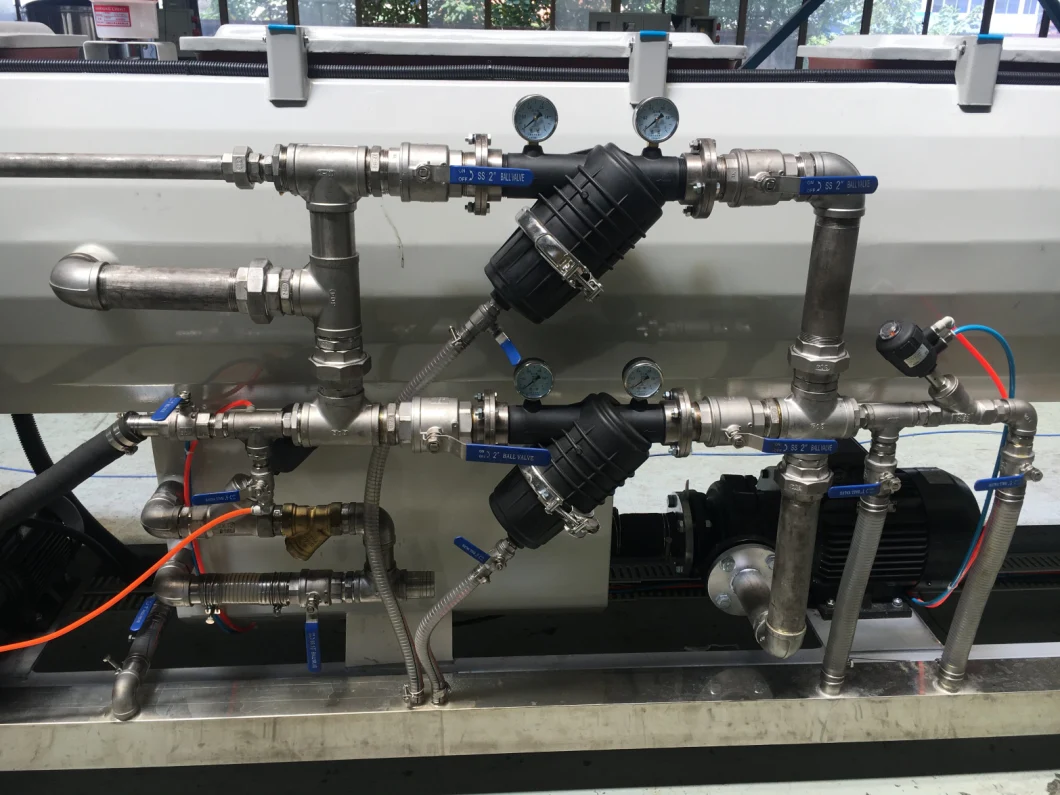

(4),Vacuum shaping water tank for pipes, cooling stereotypes, stereotypes water tank is provided with a vacuum for shaping and cooling of the vacuum system and a water circulating system, stainless steel tank, circulating water spray cooling, vacuum shaping water tank is provided with a mobile device, and left and right height regulating manual device.

(5),hauling machine for continuously, automatically and is cooled to harden the pipes from the head out, variable frequency speed regulation, control by ABB inverter, save power for client.

down frame move by electric motor design, easy operation and stable runnning.

(6),Cutting machine: by the travel switch according to the length required control, automatic cutting, and delay over the frame, implementation of water production, cutting machine with permanent switch signal for instruction, complete the cutting process, the cutting process and pipe running to maintain synchronization, cutting process by the electric and pneumatic drive, cutting machine is provided with a dust suction device, the cutting chips produced by timely aspirate, and recovery

(7),stacker: material turning movement from the cylinder through the gas path control to achieve erection, turning a limit device, when the cutting saw to cut the pipe, pipe to transport, after time delay, the cylinder into the work, realize the turning action, reach the discharging purpose. After unloading, the delay of several seconds automatic reset, waiting for the next cycle.

3,machinery technical parameter

| Pipe range | 20-110mm | 90-250mm | 110-315mm | 315-630mm |

| Extruder | SJZ51/105 | SJZ65/132 | SJZ80/156 | SJZ92/188 |

| Extruder power | 18.5kw | 37kw | 55kw | 110Kw |

| Extrusion capacity | 120kg/h | 250kg/h | 350kg/h | 700kg/h |

| Max. Production speed | 10m/min | 6m/min | 3 m/min | 1.2m/min |