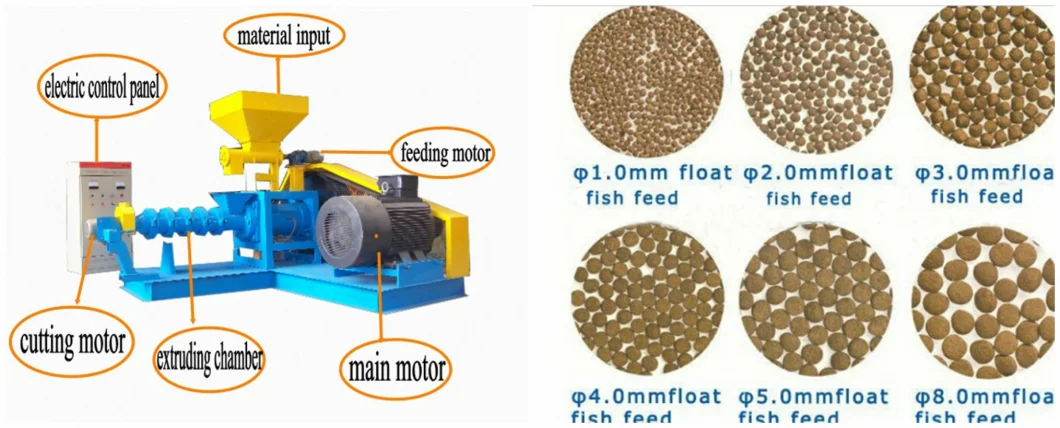

1.Product Description

a. With different moulds, the machine can produce different diameter food, such as 1.5mm, 2.5mm etc. So the food can meet different stage fish.

b. The floating fish feed pellet machine can make poultry-fodder, pet-fodder, as well as aquaculture-fodder and fishery feed.

c. It is mainly used to process the maize flour, soybean flour or compound powder, wheat bran into high grade aquatic feed pellets for fish, catfish, shrimps, dog,.cat etc.

d. According to customers' demand and production scale, floating fish feed machine includes two kinds: Dry type machine and Wet type machine.

Steps:Crushing→Mixing→Pellet making→Pellet Drying→Oil spraying→weighing, packaging.

2. Floating Fish Feed Extruder Specification

| Model | Capacity (kg/h) | Main power (kw) | Feeding power(kw) | Cutting power (kw) | Screw diameter (mm) |

| DGP40-C | 30-40 | 5.5 | 0.4 | 0.4 | Φ40 |

| DGP50-C | 60-80 | 11 | 0.4 | 0.4 | Φ50 |

| DGP60-C | 120--150 | 15 | 0.4 | 0.4 | Φ60 |

| DGP70-B | 180-200 | 18.5 | 0.4 | 0.4 | Φ70 |

| DGP80-B | 200-250 | 22 | 0.4 | 1.1 | Φ80 |

| DGP90-B | 320-350 | 30 | 1.1 | 1.5 | Φ90 |

| DGP120-B | 500-600 | 55 | 1.1 | 2.2 | Φ120 |

| DGP1350-B | 700-800 | 75 | 1.1 | 2.2 | Φ133 |

| DGP160-B | 1000-1200 | 90 | 1.5 | 2.2 | Φ155 |

| DGP200-B | 1800-2000 | 132 | 1.5 | 3.0 | Φ195 |

size can be 0.9-12mm as your demand. You just need to change the moulds to get different size pellets.

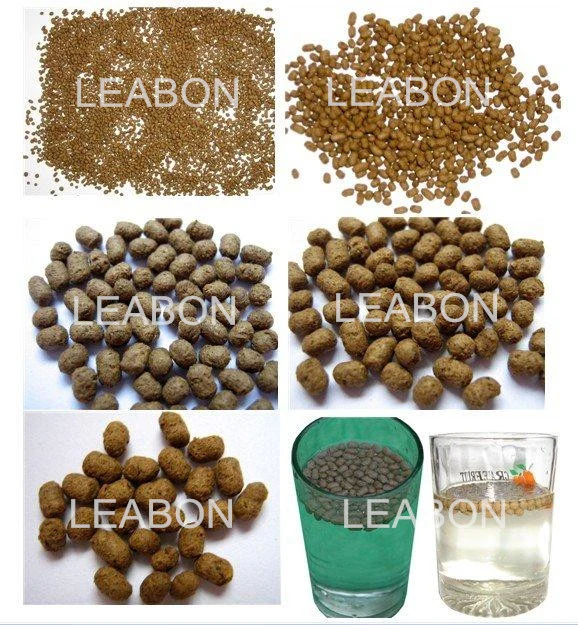

Also, the pellets shapes are various

4. More pictures:

5. RFQ:

What's your demand of this machine?

What;s your raw material to make fish feed?

Do you need the only fish feed machine or whole production line?