Waste Plastic PET Bottle Recycling Crushing Washing Drying Equipment Machine/ plastic recycling machine

Advantages:

1. Final products has good quality. When process PET bottle PE rigid scraps, final products humidity below 5%.

2. The whole line capacity between 150kg/h-2000kg/h (150kg/h,300kg/h,500kg/h,1000kg/h, 2000kg/h)

3. Parts which contact material use SUS304,thickness more than 3mm,ensure long service lift time

4. World famous brand components applied on the production line- SKF bearing,Siemens contactor,Omron temperature,FUJI invertor,Siemens PLC control etc

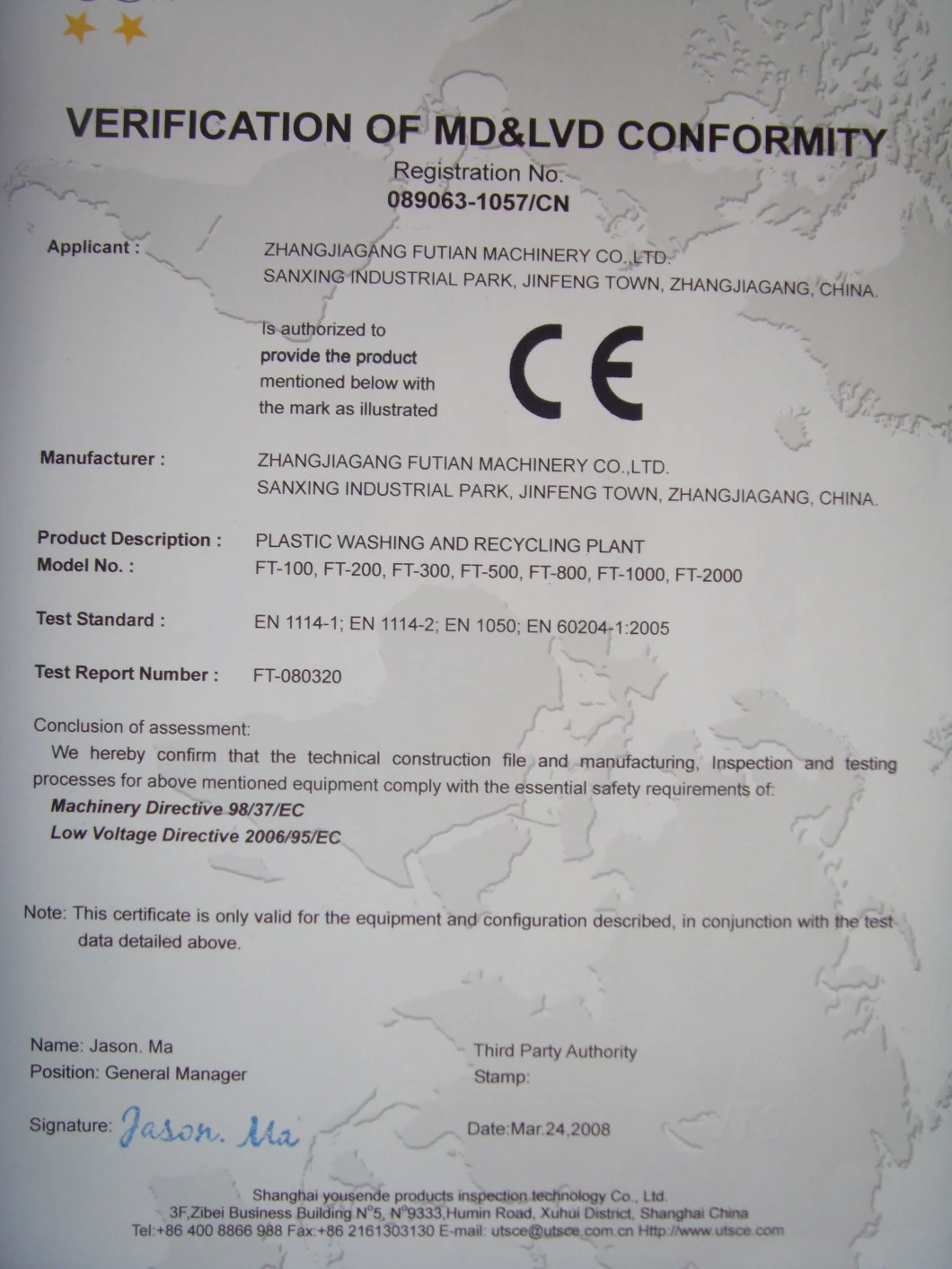

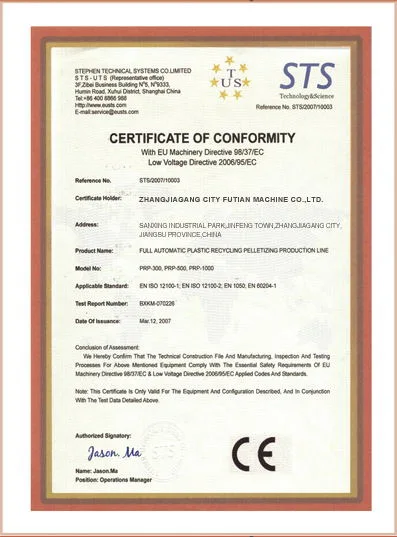

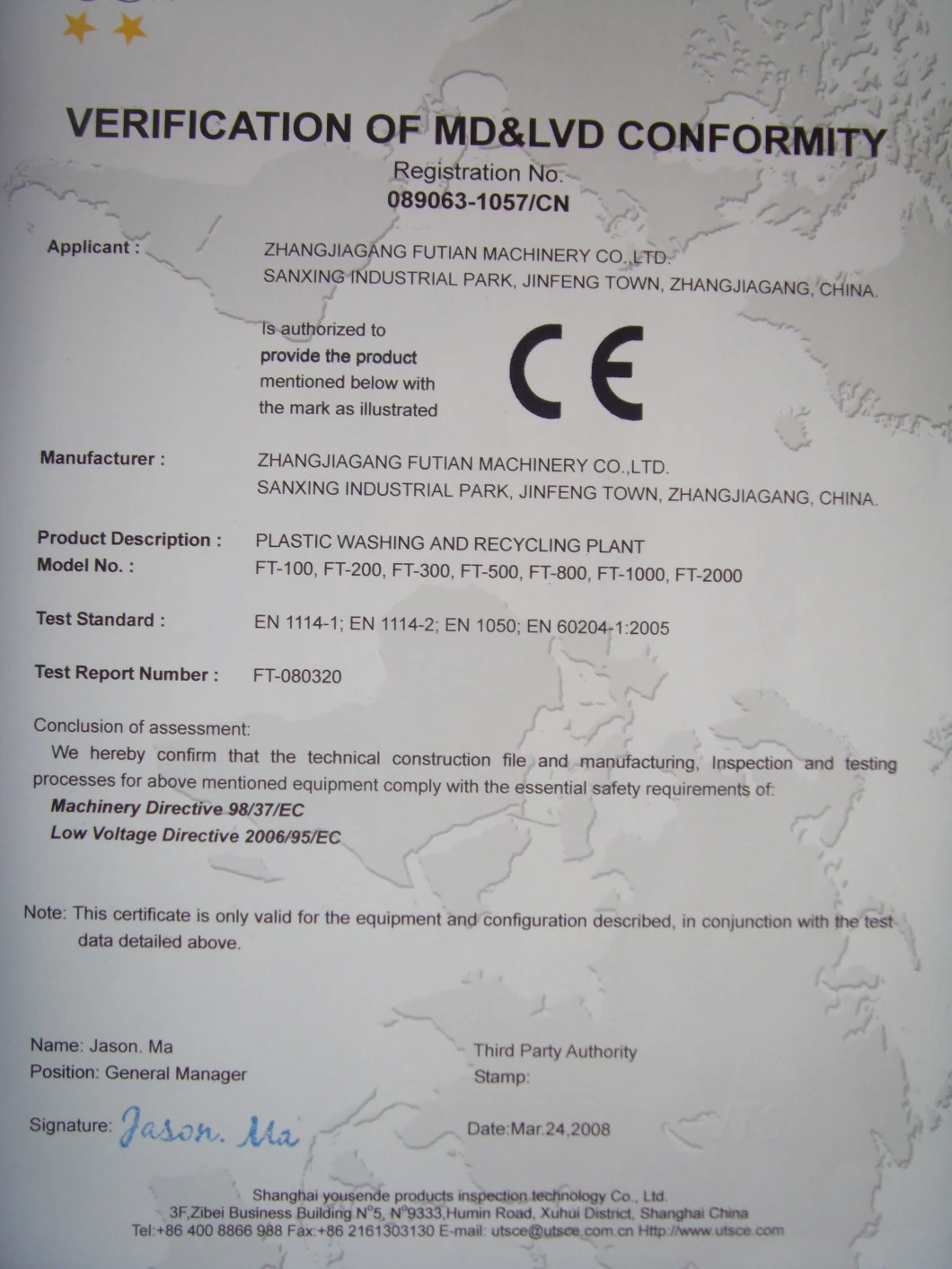

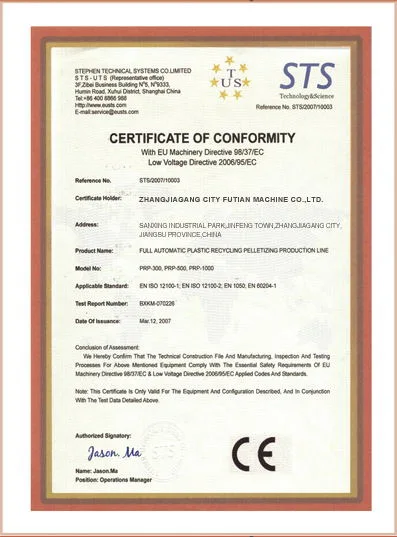

5. The whole production line with CE certification,ISO9001 certification

Working Flow:

Working Flow:

PET bottle flakes recycling/washing and cleaning equipment/ plastic crushing and washing machine

Belt conveyor →Metal detector(Optional)→ Crusher (with water) → Float washer loader→Float washing tank→Float washer loader→Float washing tank→Float washer loader→Film dewatering machine→Hot air drying system→Storage hopper→Control cabinet

related machines:

Advantages:

1. Final products has good quality. When process PET bottle PE rigid scraps, final products humidity below 5%.

2. The whole line capacity between 150kg/h-2000kg/h (150kg/h,300kg/h,500kg/h,1000kg/h, 2000kg/h)

3. Parts which contact material use SUS304,thickness more than 3mm,ensure long service lift time

4. World famous brand components applied on the production line- SKF bearing,Siemens contactor,Omron temperature,FUJI invertor,Siemens PLC control etc

5. The whole production line with CE certification,ISO9001 certification

Working Flow:

Working Flow:PET bottle flakes recycling/washing and cleaning equipment/ plastic crushing and washing machine

Belt conveyor →Metal detector(Optional)→ Crusher (with water) → Float washer loader→Float washing tank→Float washer loader→Float washing tank→Float washer loader→Film dewatering machine→Hot air drying system→Storage hopper→Control cabinet

| No | Machine name | Qty | comments | Power consumption |

| 1 | Conveyor belt | 1 set | 2.2kw | |

| 2 | Crusher PC1200, 75kw | 1set | with water inlet | 75kw |

| 3 | Friction washing | 1set | 7.5kw | |

| 4 | Screw loader | 1set | 1.5kw | |

| 5 | Screw transport machine | 1set | Stainless steel | 1.5kw |

| 6 | Steam hot washing | 1set | Stainless steel | 60kw+5.5kw |

| 7 | Screw transport machine | 1set | Stainless steel | 1.5kw |

| 8 | Friction washing | 1set | 5.5kw | |

| 9 | Floating washing tank | 1set | Stainless steel | 3kw*2+1.5kw |

| 10 | Screw transport machine | 1set | 1.5kw | |

| 11 | Horizontal dewatering machine 30 kw | 1set | 30kw | |

| 12 | Collect cyclone | 1set | ||

| 13 | Blade sharpen machine | 1set | 2.2kw | |

| 14 | extra blade | 4sets | ||

| 15 | Electrical Control cabinet | 1set |

related machines:

our service

1.Pre-sale: we given client the details technician offer,sign the sales contract etc.

2.In-sales: we supply the details layout, installation instruction,technician support for the clients.

3.After-sales: we arrange engineer to install the machinery and training the workers for client.

4.We have 24hours team to solve the after-sale problem.

5.We supply free spare parts with the machine.

6.We always update the new technology to every customer. certificate:

1.Pre-sale: we given client the details technician offer,sign the sales contract etc.

2.In-sales: we supply the details layout, installation instruction,technician support for the clients.

3.After-sales: we arrange engineer to install the machinery and training the workers for client.

4.We have 24hours team to solve the after-sale problem.

5.We supply free spare parts with the machine.

6.We always update the new technology to every customer.